Custom Pet Silicone Licking Mat Factory

Professional Pet Silicone Licking Mat processing and customization, Pet Silicone Licking Mat manufacturer, find a source factory for silicone product processing and customization, choose Jinlang products. Our factory focuses on the design, development, mold, and customized processing of silicone products, providing customers with customized solutions for silicone product processing. We can process and customize according to customers’ drawings and samples.

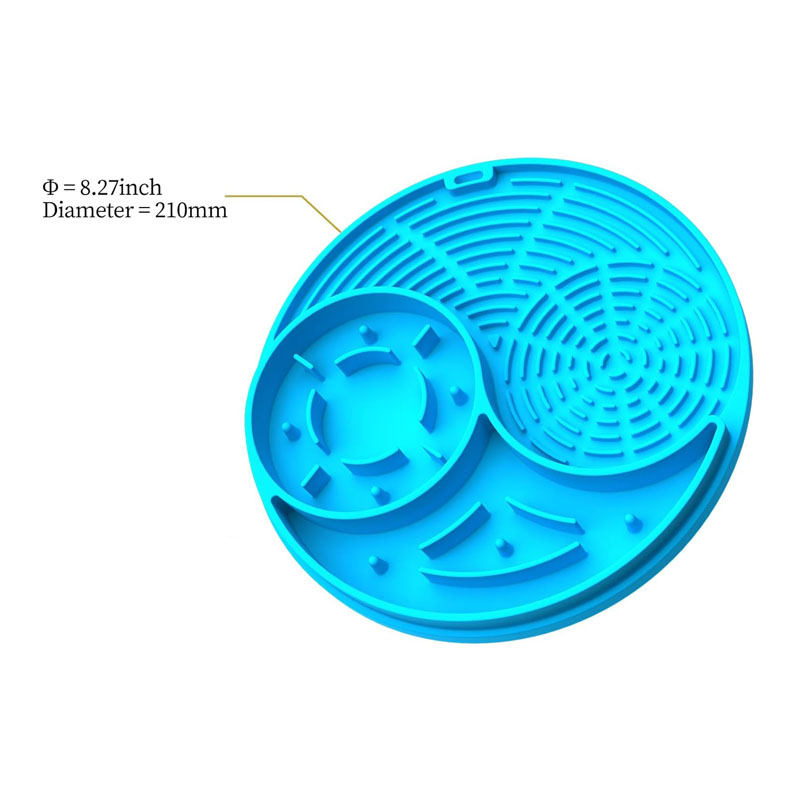

Product Name: Pet Silicone Licking Mat

Product material: Food grade silicone

Product pattern: customizable

Product color: customizable

Support customization: OEM/ODM

Sales regions: Europe, South America, Southeast Asia, North America, Northeast Asia, Middle East

Manufacturer: JINLANG

Description

Product Name: Pet Silicone Licking Mat

Product Code: JL-PET-008

Product size: customizable

Product material: Food grade silicone

Product pattern: customizable

Product color: customizable

Applicable industry: Pets

Support customization: OEM/ODM

Sales regions: Europe, South America, Southeast Asia, North America, Northeast Asia, Middle East

Manufacturer: JINLANG

Jinlang Products is a professional silicone product factory that specializes in designing, developing, molding, and customizing silicone products. The factory provides customers with customized solutions for silicone product processing. The company’s main business includes silicone products, silicone drool pouches, pet silicone products, kitchen silicone products, baby silicone products, silicone bracelets, silicone craft gifts, silicone buttons, silicone swim caps, silicone watch straps, silicone toothbrushes, silicone bottle covers, sealing rings, cosmetics covers, and other products. The company can process and customize according to customer drawings and samples.

Introduction To Factory Strength

Global Professional Silicone Product Manufacturer, Suppliers, Factory.

1. Strong Production Strength

The company currently covers an area of 6000 square meters with a building area of 12000 square meters. The company has advanced production lines, testing centers, product research and development centers, and mold processing centers in China. Provide drafting, mold making, sampling, mass production, and customized supporting services.

2. Advanced Production Equipment

The company has complete supporting equipment, using solid-state molding technology and liquid injection molding technology to produce silicone products. It uses 250T to 500T silicone vacuum molding equipment and imported precision injection molding liquid equipment for production and processing, and quickly completes vulcanization molding, with high output and excellent efficiency.

3. Professional Customized Processing Solutions

We process and customize various silicone products according to customer needs. If the customer does not have a product plan, we provide the factory with thousands of ready-made products for reference and provide detailed customization plans. Samples can be made within 1-3 days, and mass production can be carried out within 7 days. Customization can be based on drawings and samples to ensure that the products meet customer requirements.

4. Powerful Mold Workshop In The Factory

The factory is equipped with complete mold processing equipment such as CNC machining centers, EDM spark machines, CNC milling machines, CCD drilling machines, etc. Based on the number of processing orders from customers, if a certain threshold is reached, our company can provide free mold and sample making for zero cost development.

5. Customer Mold Storage Management

The factory adopts an ERP management system, builds a self built mold warehouse of over 1000 square meters, and regularly maintains and manages it. The company’s mold room provides 1-3 days to complete experimental molds and 7 days to complete mass production molds, greatly improving efficiency through one-on-one services.

6. Professional Service Team

Customers can provide drawings, samples, or design concepts, and our company can respond quickly by providing 3D drawings of the product. More than 10 senior mold design engineers with leading industry experience can meet various customized needs of customers.